How Does It Work?

How does it work?

How does magnetism affect Hydrocarbon-based combustible fluids such as gasoline, diesel fuel, kerosene, LP and natural gas?

To promote complete combustion, Oxygen must be combined with the Hydrocarbon molecule. Because the net charges of the Hydrocarbon and Oxygen molecules are both negative, there are repulsive forces, not attractive forces present. To overcome this repulsion, combustion engineers design combustion processes so that the combustion envelope is super-saturated with Oxygen. The overwhelming Oxygen concentration forces the two similarly charged molecules to be in close physical proximity to each other and eventually, combine to create the combustion climate. In essence the fuel uses the available Oxygen.

Since Fuel, like most fluids, can be ionized by an external magnetic force, it will exhibit many of the same physical-atomic characteristics as water.

When MAGNETIZED, the fuel’s Hydrocarbons are ionized to exhibit a net positive charge (as with water). The change in charge allows the fuel to aggressively attract and bond with available (negatively charged Oxygen. This creates a more comprehensive Hydrocarbon molecule with its own Oxygen supply. The end result is a more efficient and fully burning, explosive mixture which now has its own oxygen base.

When MAGNETIZED, the fuel’s Hydrocarbons are ionized to exhibit a net positive charge (as with water). The change in charge allows the fuel to aggressively attract and bond with available (negatively charged Oxygen. This creates a more comprehensive Hydrocarbon molecule with its own Oxygen supply. The end result is a more efficient and fully burning, explosive mixture which now has its own oxygen base.

Magnetizing the fuel also polarized the mixture by replacing the normally chaotic fluid with an even, positively charged uniformly aligned fuel, which, with the oxygen bonding, results in an almost total burn for complete BTU output (no hot spotting) and better fuel efficiency. The magnetized fuel also attracts and removes previous carbon and varnish build-up (similar to the scale removal action in an aqueous environment) in the jets, injectors and engine for even higher efficiency. Cleaning to Factory – New Specs, thereby running a cleaner, more efficient engine, which of course lasts longer with improved performance.

What Can a Magnet Technology Do for Diesel Powered Vehicles?

In addition to increasing fuel efficiently, when properly magnetized, diesel fuel will resist gelling. (Gelling is a temperature induced “crystallization” that can be considered somewhat analogous to the scaling mechanism in an aqueous solution). This means that during cold weather, special fuel additives may be eliminated. Also, for the same oxygen bonding and cleaning reasons as outlined above, immediately apparent is the increase in available power and the marked reduction in the exhaust smoking normally associated with diesel power.

After Installation, what type of behavior can be expected from a newly MAGNETIZED car?

Immediately evident will be an increase in the power/mpg. This is the newly energized fuel exploding in the combustion chambers. Depending upon the carbon & varnish condition of the system, the extra mpg may be reduced temporarily. This is a result of the MAGNETIZED fuel’s cleaning capability, dissolving the carbon and the varnish build-up from within the system. It occurs when tiny particulates may briefly impede the fuel flow. The particulate will dissolve. The power will then return, signifying the completion of the “cleaning” stage. At this point, the jets, lines, and injectors return to peak efficiency.

Immediately evident will be an increase in the power/mpg. This is the newly energized fuel exploding in the combustion chambers. Depending upon the carbon & varnish condition of the system, the extra mpg may be reduced temporarily. This is a result of the MAGNETIZED fuel’s cleaning capability, dissolving the carbon and the varnish build-up from within the system. It occurs when tiny particulates may briefly impede the fuel flow. The particulate will dissolve. The power will then return, signifying the completion of the “cleaning” stage. At this point, the jets, lines, and injectors return to peak efficiency.

Success Story:

Rapid Line, Inc.

Turning Natural Gas Expense into Profits

GMX Natural Gas Application Test Results In Canada

1.9 MB PDF file – click/right click on link above

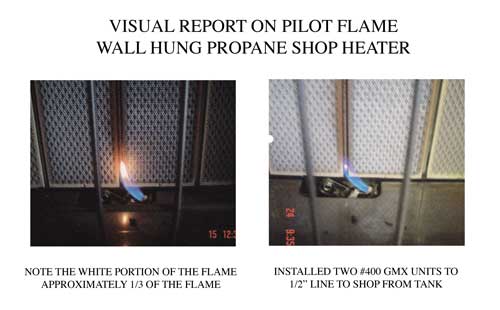

click on image above for enlargement

Installation Guide for

GMX MAGNETIC FLUID FUEL DEVICES

Small vehicles– 1 GMX Model 400

Midsize vehicles — 2 GMX Model 400s

SUVs — 2 GMX Model 400s

Pickups — 2 GMX Model 400s

Motor Homes– 2 GMX Model 400s

Buses — 2 GMX Model 800s and 2 GMX Model 400

Commercial Vehicles — 2 GMX Model 800s and 2 GMX Model 400

Semi-Trucks — 2 GMX Model 800s and 2 GMX Model 400

GMX Corporate recommends the following

for natural gas line GMX applications:

- Main line to home. Between the meter and the hook up, if there is a flex, plex, stainless steel, or copper, use at least 2 GMX units. 3 is even better as the longer the magnetic field, the better the savings.

- Treat each application as well if there is flex line to the appliance–gas furnace, hot water heater, range, dryer, gas fireplace, etc. GMX recommends 2 units on each application.

- GMX recommends the following for natural gas and propane applications:

1/4 to 1/2″ line – 3 GMX Model 400s, spaced 1/2″ apart

5/8 to 1″ line – 3 GMX Model 800s, spaced 1″ apart

1 to 1 3/4″ line – 4 GMX Model 848s, spaced 1″ apart

2″ line – 4 GMX Model 8000s spaced 1″ apart

3″ line – 4 GMX Model 8000s spaced 1″ apart

4″ line – 6 GMX Model 8000s spaced 1″ apart

5″ line – 7 GMX Model 8000s spaced 1″ apart

6″ line – 8 GMX Model 8000s spaced 1″ apart

7″ line – 9 GMX Model 8000s spaced 1″ apart

8″ line – 10 GMX Model 8000s spaced 1″ apart

9″ line – 11 GMX Model 8000s spaced 1″ apart

10″ line – 12 GMX Model 8000s spaced 1″ apart

11″ line – 13 GMX Model 8000s spaced 1″ apart

12″ line – 14 GMX Model 8000s spaced 1″ apart

13″ line – 15 GMX Model 8000s spaced 1″ apart

14″ line – 16 GMX Model 8000s spaced 1″ apartLines that are made of iron can be swapped out for stainless steel for where the application of GMX Units are to be placed

Installation Instructions for

GMX MAGNETIC FLUID FUEL DEVICES

On small vehicles, use 1 GMX Model 400. Place the unit at least 8-12 inches upstream from the area to be treated. Place it 8-12 inches after any pump, filter, or other turbulence causing device. The direction of flow of the fluid being treated does not make any difference.

Place the unit 6-12 inches away from any high heat sources, for example, the manifold and exhaust system. Place it 12 inches away from the diagnostic control centers and sensors. The unit should be mounted on the fuel line after the filter, before the carburetor. On fuel injected engines, mount the unit on the line to the engine, not the return line.

On midsize vehicles, sport utility vehicles, pickups, diesel pickups, buses, motor homes–follow the above directions, but install 2 GMX Model 400s instead of one. Place the units in tandem.

For semi trucks–install 1 GMX Model 800 and 1 GMX Model 400. Place the GMX Model 800 on the main fuel line between the fuel tank and the engine’s fuel transfer pump. Place the GMX Model 400 between the fuel transfer pump and the fuel injection pump manifold.

So far, we are finding a minimum savings of 20% having GMX units on natural gas lines.

For natural gas line installations:

-

If the main line has black iron, you cannot install the units on it. If the connection between the meter and hook up is flex line, then install 2 Model 800s on it.

-

If you cannot install it on the main line because there is no flex line, then install the units on the flex line for each application.

-

If the flex line, example on a gas furnace, is 3/4-1″, then install 2 Model 800s.

-

If the flex line is 1/2″, example on some hot water heaters, then install 2 Model 400s.

-

Some homes may need 2 Model 800s and 4 Model 400s, depending on what they heat with gas.

-

For commercial applications, use the sizing chart to determine what is needed. For example, if the main line is 3″ and is of stainless steel or flex, then install 4 Model 8000s.